CRIATERRA’S ZERO-CEMENT BIO-GEO STONE REVOLUTIONIZES PRECAST BUILDING PRODUCTS

OUR CEMENT-FREE + KILN FREE TECHNOLOGY PRODUCES LOW CARBON MASONRY BLOCKS, CLADDING AND TILES

WE ARE DECARBONIZING THE PRODUCTS THAT WILL BUILD SUSTAINABLE CIRCULAR CITIES

RE-CREATe

By CRIATERRA Innovations

This project has received funding from the European Union's Horizon 2020 research and innovation programme under grant agreement No 946255

INTRODUCING RE-CREATE

Can kiln firing and fossil fuel combustion be eliminated from manufacturing precast products such as tiles and blocks?

YES,

it can. And that is what we set out to accelerate in our RE-CREATE project based on Criaterra’s technologies.

What is RE-CREATE?

RE-CREATE is our most innovative thinking at CRIATERRA.

In RE-CREATE we implemented CRIATERRA’s core technologies into new applications and industrial processes and took important steps towards bringing our first products to the European market,

Criaterra’s approach is to provide highly ecological, functional and economical solutions for buildings with a business model that is highly scalable.

CRIATERRA products are a win-win-win for the manufacturer, builder and building resident. They are also a giant win for the environment.

The Criaterra team is a passionate and dedicated team with expertise in industrial design, sustainability, materials science, building materials, structural engineering and energy efficiency improvements.

With our unique skills we develop technologies in a comprehensive approach that encompasses every aspect of the product, beginning at the level of the individual molecule through the final product. We ensure compliance with the standards and regulations for our products.

We then develop and apply solutions for low carbon industrialization that fit into any partner manufacturing line, which enables low capital investment.

We work closely with market experts to understand customer needs and requirements and build robust sale channels.

At CRIATERRA Innovations we aim to drive green construction towards a circular reality and develop the highest quality sustainable green building materials. These materials are designed to outperform traditional building materials and to be priced for widespread adoption. To reach our goals, we have established a strategic technology optimization plan, which we have called RE-CREATE.

The RE-CREATE innovation project expands our product portfolio and optimizes our production technology – making it faster and more efficient. It also reduces production costs, which will translate into the best products at affordable prices.

RE-CREATE also laid the foundation for future development of additional building products such as masonry blocks.

How do we do it?

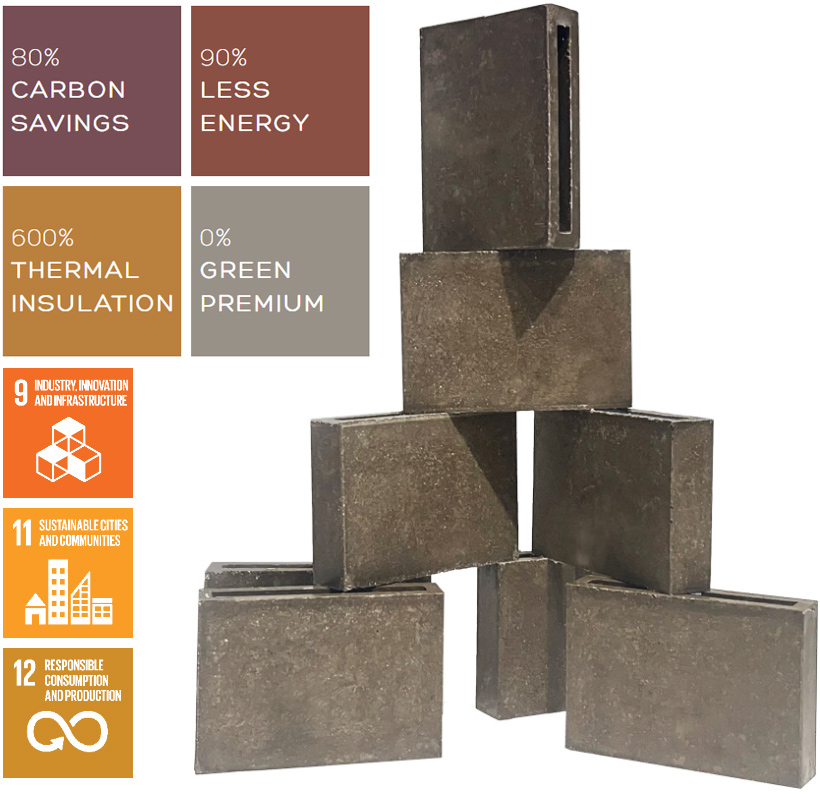

CRIATERRA completely eliminates the most environmentally harmful elements in the traditional production process of materials such as concrete and ceramics. Our innovative technique uses only 10% of the energy used in conventional building material production and creates less than 8-15% of the emissions of these conventional methods. Our process creates no waste and uses up to 70% upcycled natural content from quarry waste.

Our first product is a series of interior wall tiles. This product was selected to enable the company to build out the different platforms required to successfully launch all Criaterra products, including a complete solution that can be integrated into partner manufacturing facilities, a market development plan and a brand platform. All these milestones will serve future products, including outdoor cladding and masonry blocks.

How scalable is our technology?

Our technology has been developed to be unlimited in scalability. All materials used in our mixtures are readily available

and up to 70% can be upcycled materials from agriculture or quarry by-products.

During our RE-CREATE project, we developed new solutions/methods to fully automate or semi automate

current manual processes and optimize our pilot production line.

RE-CREATE FOR OUR PLANET

When creating green building products, we at CRIATERRA Innovations believe it is not enough to make minor reductions in ecological footprint.

CRIATERRA redesigned the entire lifecycle of these products from an eco-innovative protocol, while ensuring sustainability, strength, and affordability. The CRIATERRA technology allows the creation of a new generation of building materials designed to support the transformation of the building sector into a resource efficient, circular economy.

BEYOND RE-CREATE

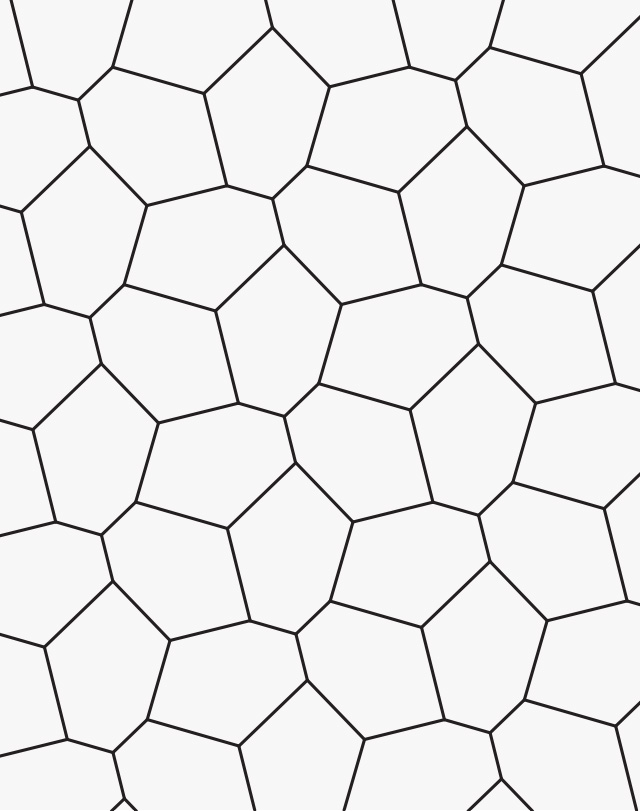

CRIATERRA’S technology enables products that can replace the most basic construction products, including the common masonry block. We manufactured advanced prototypes with high functional properties.

One of our goals is to mass-produce a smartly designed masonry block, which will offer superior thermal insulation.

CRIATERRA’S innovative technology enables the production of low carbon, circular and nearly zero-energy construction solutions for many precast materials, including tiles and masonry blocks.

CRIATERRA products meet or exceed the constructive properties of widely used products, but Criaterra products do not contain any synthetic binder or cement, instead they contain Criaterra’s proprietary natural binder.

This has far-reaching climate benefits. First, at the manufacturing stage, this has 2 important impacts:

- The current dependence on fossil fuel combustion to reach extremely high kiln temperatures can be avoided. Criaterra manufacturing saves 90% of the energy and can be powered from renewable sources.

- The current harmful process of burning off the carbon that is naturally embedded in the raw materials, releasing it into the atmosphere, is avoided entirely.

The damaging processes taking place in the manufacture of cement and ceramic based materials today are the biggest challenges toward reaching climate goals in this industry. They account for 3.29 Gigatons of CO2e emissions per year.

Criaterra’s solutions enable zero process emissions, zero fossil fuel dependence and zero waste generation. This is the most direct approach to reaching our climate goals. This approach has strong advantages over solutions that rely on offsets for a given carbon footprint, to achieve “net zero”.

Criaterra targets one of the biggest and most urgent climate challenges: the process of kiln firing of materials in the building industry, a process that is required in the manufacture of cement and ceramic products for buildings.